Seam sealers are vital for protecting vehicles and machinery from leaks, moisture, and environmental damage. Proper application involves cleaning, drying, and sanding surfaces to enhance adhesion, with optimal conditions at moderate temperatures and low humidity. Effective sealing prevents water intrusion, enhancing aesthetics and structural integrity in autobody repairs, including hail damage repair, ensuring long-lasting results.

“Seam sealing is a vital process in ensuring the integrity and longevity of various materials, from fabrics to construction projects. This article guides you through the essential safety tips for handling seam sealer during its application. We’ll start by exploring the purpose and types of seam sealers, followed by a detailed look at preparation techniques to optimize application conditions. We’ll then delve into practical application methods for effective sealant use, ensuring both efficiency and safety.”

- Understanding Seam Sealer: Purpose and Types

- Preparation: Ensuring Optimal Application Conditions

- Application Techniques for Effective Sealant Use

Understanding Seam Sealer: Purpose and Types

Seam sealers are essential materials used in various industries to create strong bonds and prevent leaks. In the context of seam sealer application, understanding their purpose and types is crucial for ensuring optimal results, especially during autobody repairs following a fender bender. These sealants are designed to fill and seal joints or seams, offering protection against moisture, chemicals, and environmental factors.

Different types of seam sealers cater to specific needs, ranging from durable, high-performance options suitable for heavy industrial applications to more flexible, user-friendly varieties for everyday use in tire services. Whether used in autobody repairs to reseal a cracked paneling or to maintain industrial machinery, the right seam sealer choice is key to achieving long-lasting protection and preventing future issues.

Preparation: Ensuring Optimal Application Conditions

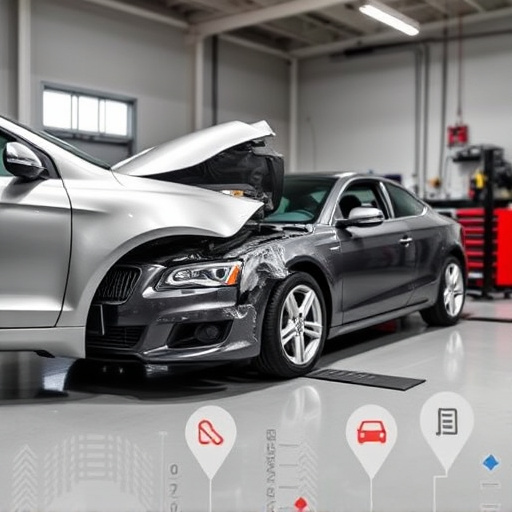

Before applying seam sealer, proper preparation is key to achieving a durable and professional finish, whether in automotive repair or autobody repairs. Ensure the surface is clean, dry, and free from any contaminants like grease, dust, or loose paint. This includes sanding the area lightly to create a rough texture that promotes adhesion. Ideal application conditions involve moderate temperatures, typically between 50°F to 80°F (10°C to 27°C), and low humidity to prevent premature curing and ensure even coating. In car bodywork services, maintaining these optimal conditions can significantly impact the effectiveness of the seam sealer application.

Application Techniques for Effective Sealant Use

Proper seam sealer application techniques are key to achieving a durable and effective seal, especially in automotive repair and dent repair scenarios where preventing water intrusion is crucial for long-lasting results. The process begins with thorough surface preparation; ensure all seams are clean, dry, and free from debris. A smooth base ensures the sealer adheres properly. Use a thin, even layer of seam sealer to fill any gaps or cracks, applying it with a suitable tool like a spatula or brush designed for this purpose.

For best results in hail damage repair, pay close attention to corner and edge seams, as these are particularly vulnerable. Allow the sealer to dry according to the manufacturer’s instructions before curing completely. Proper application techniques not only enhance the aesthetics of the repaired area but also ensure its structural integrity, protecting against elements like moisture that can compromise the overall quality of the repair, whether it’s for a car, truck, or other vehicle.

When applying seam sealer, proper preparation and technique are key to achieving a durable seal. By understanding different types of seam sealers and optimizing application conditions, you can ensure effective protection for various materials. Remember to always follow safety guidelines, use personal protective equipment, and work in well-ventilated areas during the sealing process. With these tips in mind, you’re ready to tackle any seam sealer application with confidence, ensuring long-lasting results.