Seam sealers, crucial for auto repairs, require understanding diverse formula types and their applications. They enhance structural integrity, prevent leaks, and boost durability by creating robust bonds between joints. High-quality applicator tools ensure precise, even coatings, while best practices like cleaning, priming, and adhering to temperature guidelines maximize adhesion and protection against moisture and corrosion.

“Enhance your crafting or repair skills with this comprehensive guide to effective seam sealer application. From understanding the various types of seam sealers and their unique roles, to mastering precise application techniques using essential tools, you’ll learn how to achieve strong bonding results every time. By following best practices detailed in this article, you’ll revolutionize your project outcomes.”

- Understanding Seam Sealer Types and Their Roles

- Essential Tools for Precise Application Techniques

- Best Practices for Achieving Strong Bonding Results

Understanding Seam Sealer Types and Their Roles

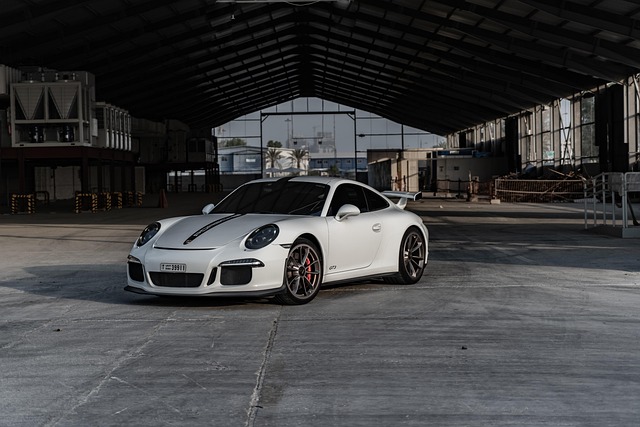

Seam sealers are essential components in various industries, particularly in automotive repairs like car collision repair and car scratch repair, where they play a pivotal role in ensuring structural integrity and water tightness. Understanding the types of seam sealers available is crucial for the effective seam sealer application process in car bodywork or any other industrial fabrication. These sealants can be categorized based on their composition, such as silicone, polyurethane, or rubber-based formulas, each with unique properties tailored to specific applications.

The role of a seam sealer goes beyond mere waterproofing; it involves creating a robust bond between joints, preventing leaks, and enhancing the overall durability of the repair. In car collision repair, for instance, applying the right seam sealer is vital to restore the vehicle’s structural integrity after bodywork repairs. Different sealers have varying levels of flexibility, resistance to extreme temperatures, and chemical compatibility, making some more suitable for exterior applications, while others are designed for internal joints where flexibility is paramount.

Essential Tools for Precise Application Techniques

When it comes to achieving a seamless finish in auto body repairs or automotive restoration projects, the tools you use play a pivotal role. Precise application techniques are key to ensuring that your seam sealer adheres perfectly, creating a durable and aesthetically pleasing result. Essential tools for this process include high-quality applicator guns and brushes designed specifically for applying sealants. These tools enable you to control the flow of the sealer, allowing for consistent and even coating, especially in hard-to-reach areas.

For intricate details and curves, a fine-tipped brush is invaluable, ensuring meticulous application. In an automotive body shop, where precision is paramount, using these specialized tools can make all the difference between a flawless finish and one with visible imperfections. The right tools empower you to master the art of seam sealer application, leaving behind a professional touch on every project, whether it’s for auto body repairs or intricate automotive restoration work.

Best Practices for Achieving Strong Bonding Results

For achieving strong bonding results during a seam sealer application, it’s crucial to follow best practices designed for optimal adhesion and long-lasting protection. Begin by ensuring a clean, dry surface free from any debris or oils that could impede the adhesive properties of the sealer. This often involves thorough washing and degreasing, especially in automotive body work or collision repair services where paintless dent repair techniques are employed.

Next, proper preparation of the seams is key. Use fine-grit sandpaper to smooth out any roughness, creating a consistent surface for better sealant penetration. Remove all dust and residue before applying a primer designed to enhance adhesion. Following manufacturer guidelines for application time and temperature ensures that the seam sealer reaches its maximum potential, providing durable protection against moisture and corrosion, whether for automotive body work or other applications.

When it comes to effective seam sealer application, the right tools and techniques are essential. By understanding different seam sealer types and adhering to best practices, you can achieve strong bonding results for various applications. Always prioritize precision with your chosen tools to ensure a high-quality, durable seal every time.