Brushing offers precision for detailed work but is time-consuming, while a caulk gun provides speed and efficiency for large-scale seam sealer application. Guns control flow rate and pressure, minimizing waste, making them ideal for auto body shops, especially collision repair. Brushing suits smaller, precise tasks on luxury vehicles; caulk guns require skill for intricate surfaces but are faster, potentially lowering costs in repairs.

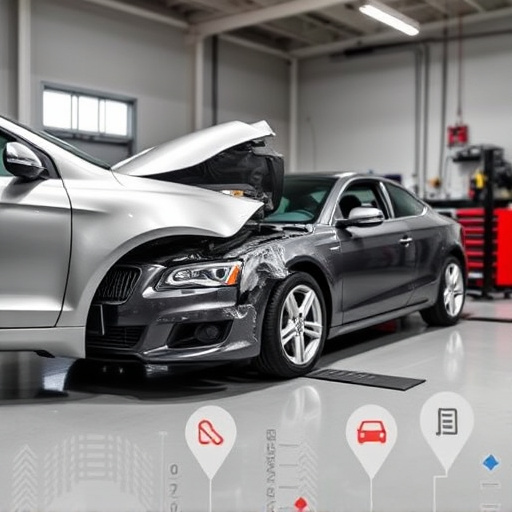

When it comes to sealing seams, choosing between a brush or caulk gun method depends on your project’s unique needs. This guide explores the advantages and drawbacks of each technique for effective seam sealer application. Brush application offers precise control and is ideal for intricate details, while caulk guns excel at rapid, large-scale sealing. Understanding these methods allows you to select the best tool for a seamless finish, ensuring long-lasting protection against leaks and damage in various applications, including construction and automotive repairs.

- Brush Application: Pros and Cons for Seam Sealer

- Caulk Gun: Advantages and Techniques for Sealing

- Choosing Between Brush and Caulk Gun Methods

Brush Application: Pros and Cons for Seam Sealer

Using a brush for seam sealer application has its advantages. It allows for precise control over the product, making it ideal for intricate or hard-to-reach areas. This method is particularly useful in Mercedes-Benz collision repair where meticulous detail is required to match original factory finishes. The brush also enables a more even distribution of the sealer, resulting in a smoother and more professional finish. However, brushing can be time-consuming, especially for larger projects, as it demands consistent pressure and technique to avoid uneven coating.

Moreover, while brushes offer control, they may not be suitable for applying thick or viscous sealers. In collision repair centers, where car paint services are provided, a brush might lead to wastage and an inconsistent final layer. Conversely, brushing can create fine lines and patterns that can be challenging to replicate with other methods, making it more suitable for specialized tasks rather than large-scale seam sealer application.

Caulk Gun: Advantages and Techniques for Sealing

A caulk gun is a versatile tool for applying seam sealers, offering several advantages over traditional brushing methods. Its primary benefit lies in its efficiency; it can quickly dispense large volumes of sealer with minimal effort, making it ideal for sealing larger surfaces or tight spaces. This method is particularly useful for auto body shops and Mercedes-Benz repairs, where precision and speed are paramount. The gun’s design allows for precise control, enabling users to apply the sealer evenly and accurately, ensuring no overspray or waste.

Techniques for using a caulk gun involve controlling the flow rate and pressure to achieve the desired consistency of the sealer. This method is excellent for filling gaps and cracks, providing an airtight seal that prevents water intrusion and protects against corrosion, which is crucial for maintaining vehicle integrity in various weather conditions. Compared to brushing, it’s a faster process, reducing labor time and potentially lowering costs in car scratch repairs or other auto body restoration work.

Choosing Between Brush and Caulk Gun Methods

When it comes to applying seam sealer in autobody repairs, choosing between a brush and a caulk gun method depends on various factors. For smaller, more precise areas, a brush allows for better control over the amount of sealer applied, making it ideal for detailing work on luxury vehicles. This manual approach ensures even coverage and can be easily adjusted to hard-to-reach spots.

On the other hand, a caulk gun is best suited for larger, continuous sealing tasks commonly found in collision repair shops. Its rapid application makes it more efficient for covering broad surfaces, saving time during the sealing process. However, it may require more skill to maintain consistent pressure and control over the sealer flow, especially when dealing with intricate or curved surfaces often encountered in autobody repairs.

When deciding between brush application or a caulk gun for seam sealer application, consider your project’s scale, surface preparation, and desired finish. Each method offers unique advantages and is best suited to specific scenarios. Brush application excels for precise, detailed work and smaller projects, while caulk guns are more efficient for larger areas, achieving faster, consistent sealing. By understanding the pros and cons of each technique, you can make an informed choice to ensure optimal results in your seam sealer application.